NAMEPLATE SPECIFICATIONS

Material Line-up

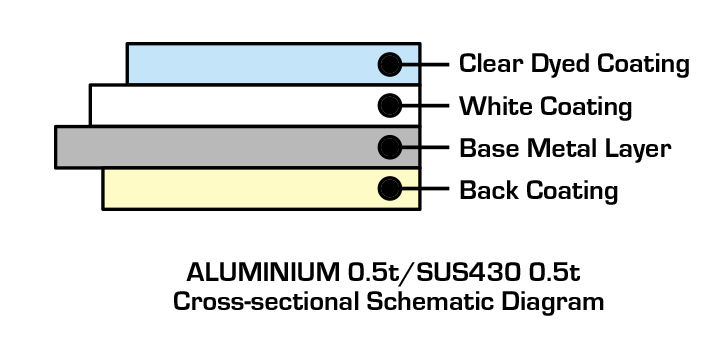

SUS430

Thickness : 0.5t

Color : White (Matte)

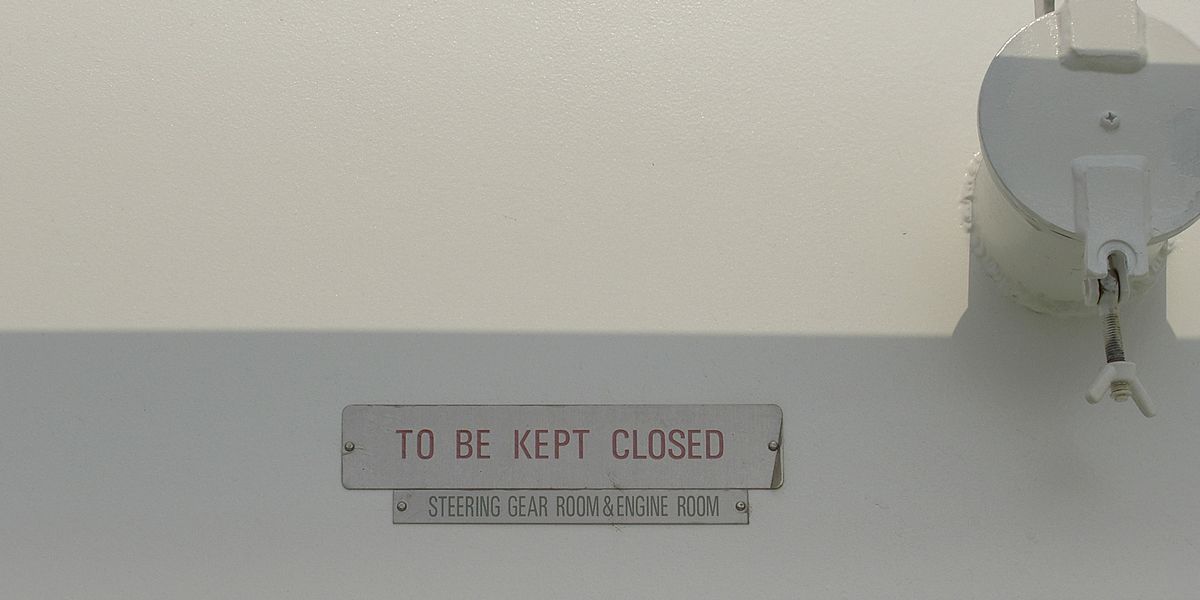

Use : Color valve nameplates, General nameplates, Caution boards, etc.

ALUMINIUM

Thickness : 0.5t

Color : White

Use : General nameplates, Room nameplates, Caution boards, Arrangement Plans, etc.

Our nameplates are manufactured by penetrating ink into the resin coated metal plate to express the design, and the metal surface is well protected. In addition, the resin (clear coating) layer contains anti-pollution agents and UVA to prevent fading. The back side is also coated with a clear coating to provide excellent corrosion resistance.

General Characteristics

Parameter & Test Method |

Aluminium 0.5t |

SUS430 0.5t |

SUS304 1.0t |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Paint Film Hardness : JIS G 3312 Pencil Hardness Test (load: 9.81N(1kgf)) |

F |

H |

H |

||||||||

Paint Film Adhesion:JIS G 3312 Cross-scoring Test |

100/100 |

100/100 |

100/100 |

||||||||

Corrosion Resistance : JIS K 5400 Salt Water Spray Test 35℃., 500 hours |

No Irregularities |

No Irregularities |

No Irregularities |

||||||||

Humidity Resistance : JIS K 2246 49℃, 98%RH, 500 hours |

No Irregularities |

No Irregularities |

No Irregularities |

||||||||

Bending Adhesion : JIS K 3312 20℃, 180deg bending test |

5T |

5T |

7T |

||||||||

Impact Resistance : JIS K 5400 Compliant Impact Tester (1.2in / 500mm / 1kg) |

No peeling |

No peeling |

No peeling |

||||||||

Durability : JIS K 5400 Sunshine Weather meter test 200 hours (cyan) |

ΔE≦7 |

ΔE≦7 |

ΔE≦7 |

||||||||

Solvent Resistance : 100 times back and forth with Xylol-impregnated gauze with a load of 1kg on 1㎠. |

No peeling / dissolution |

No peeling / dissolution |

No peeling / dissolution |

||||||||

Stain Resistance : Apply black permanent marker and leave for 24 hours. Then wipe with ethanol. |

Can be wiped off |

Can be wiped off |

Can be wiped off |

||||||||

Alkali Resistance : Immersed in 3% NaOH solution for 24 hours at room temperature, then observed for appearance |

No Irregularities |

No Irregularities |

No Irregularities |

||||||||

Acid Resistance : Observed after immersion in 3% HCl solution for 24 hours at room temperature |

No Irregularities |

No Irregularities |

No Irregularities |

||||||||

Detergent Resistance (1) : Observed after immersion in a standard aqueous solution of dish detergent (room temp. 24hours) |

No Irregularities |

No Irregularities |

No Irregularities |

||||||||

Detergent Resistance (2) : Observed after immersion in a standard aqueous solution of household detergent (room temp. 24hours) |

No Irregularities |

No Irregularities |

No Irregularities |

||||||||

Detergent Resistance (3) : Observed after immersion in a standard aqueous solution of chlorine bleach (room temp. 24hours) |

No Irregularities |

No Irregularities |

No Irregularities |

Environmental Characteristics

Clean Making Process

No organic solvents, photosensitive materials etc. are needed during production

Recyclable

Recyclable / disposable as normal metal materials.

Safer Inks

Inks contain no enamel, lead or copper.

Conforms to the Latest JIS Standard

Nippon Maritime Display, as a leading company in the field of marine nameplates, has participated as a member of the committee of Japan Ship Technology Research Association (JSTRA) for JIS standardization for marine nameplates. This project came to fruition as a newly established JIS standard on March 31, 2008.

NMD's ship's nameplates conform to JIS F0104 (Japanese Industrial Standard: Ship's Nameplate Design Standard).