3D-MDS - 3D SCANNING SERVICE

This page provides an overview of our onboard 3D scanning service for equipment retrofitting.

Just Take the 3D Scanning First!

Retrofitting equipment to an existing ship is a major project that requires a great amount of time and effort, no matter whether it is a ballast water treatment system (BWMS) or exhaust gas cleaning system (EGCS). Selection of equipment and vendors, meetings, measurement, design, installation, and operation are part of the retrofitting process.

It would be ideal if the entire process could be done in one go, but unfortunately this is not possible as ships are in permanent movement.

You cannot always take onboard measurement freely at a convenient location or time, even though you are otherwise ready to start the retrofitting process.

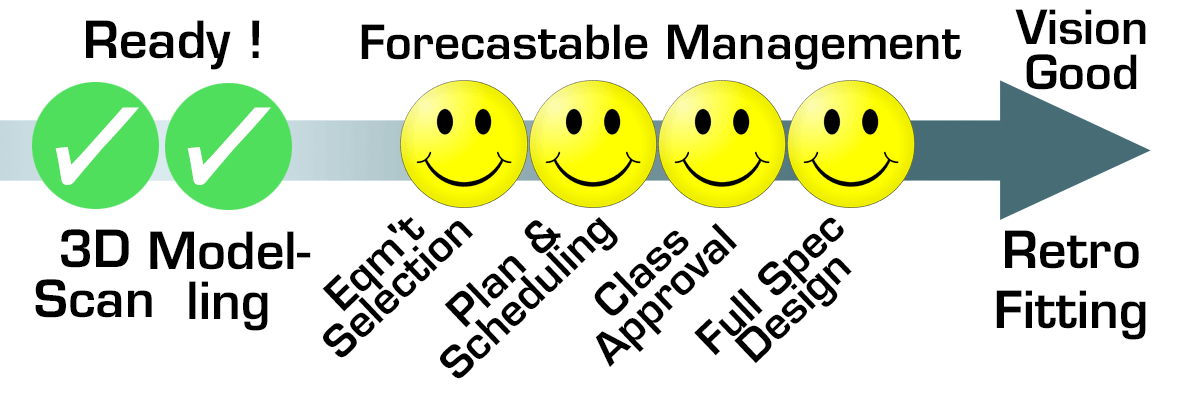

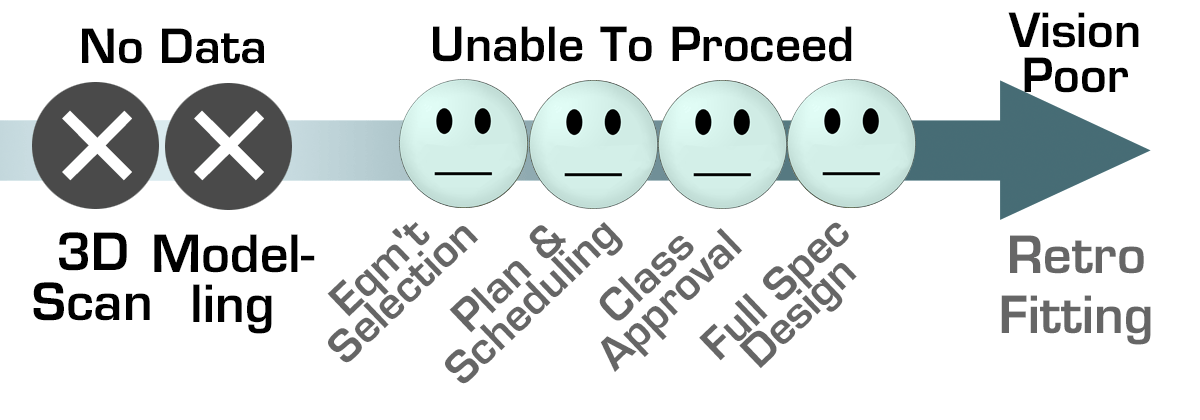

This is our proposal : "Take 3D scanning first when you can do it, even if you are otherwise not ready to proceed the retrofitting process."

Making the Rest of Your Process Much Easier

A retrofitting project cannot be started without the latest data of actual status, since each ship, even sister ships, changes in various ways after completion. It is not possible to retrofit based on the builder's finished drawings !

However, if the 3D scanning process has been completed, you will be able to proceed with the subsequent processes, such as equipment model selection, class approval or detailed designing, at your own pace.

For example, you can plan the retrofit installation schedule in conjunction with future drydocking and special surveys. Or, you may want to seize the opportunity when the vessel arrives at an easily accessible port near your base. Or, you can take the time to select the right model while monitoring the certification/approval status of the specific models.

This way, you can make sure that the biggest uncertainties in the schedule are removed.

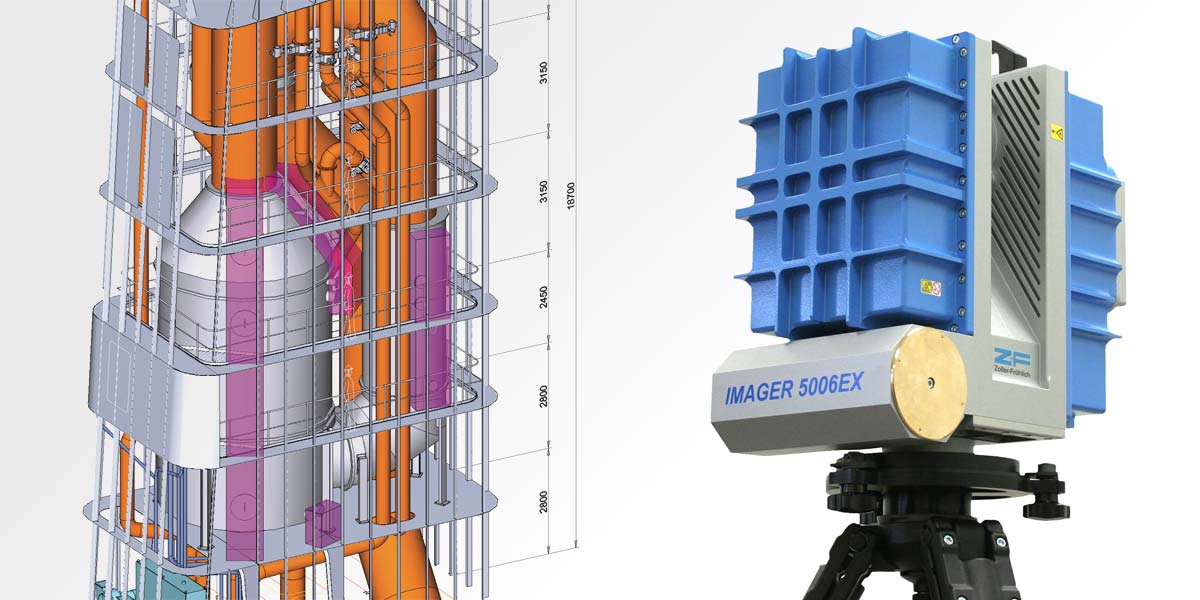

Scanner Line-up

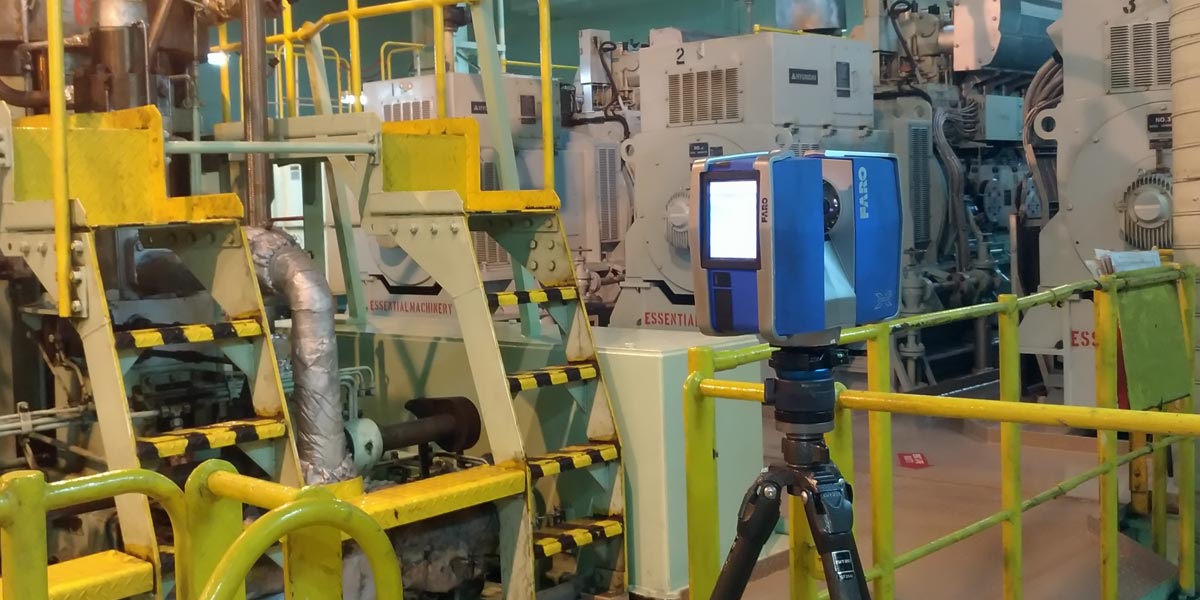

To meet the diverse needs of our customers, we have a wide range of scanners, including explosion-proof Z+F Imager 5006EX, which can be used in hazardous areas.

Worldwide Service in Covid-19 Era

While travel restrictions due to the spread of the coronavirus have not been lifted, we are able to use our international network to provide 3D measurement services in Japan and around the world.

We have performed measurements at various ports in Europe, North America, Middle East and Asia, including USA, Japan, Singapore, Taiwan, Malaysia and UAE.

Please contact us for details.

Advantages Backed by a Proven Track Record

- Top-class achievements in Japan

- for BWMS as well as EGCS

- No model selected yet? No Problem !

- Latest 1st-class scanners lineup

- Any type of merchant ships incl. hazardous cargo carriers

- Can do 3D-scan worldwide

- Knowledge on ship design and ship operation

- Familiar with shipping & shipbuilding practices

NAVIGATE FURTHER :

Marking

Engineering

About NMD

NMD GROUP CO. LTD.

© 2003-2025, all rights reserved.