NAMEPLATE - QUALITY

This page explains the quality and features of NMD's metal ship nameplates.

Durable, Resistant to Weather & Corrosion

Seawater, sunlight, high or low temperatures. Exposed areas on ships, especially on deck, are extremely harsh environments. As a product specialized for ships, it must first and foremost have weather resistance, durability, and corrosion resistance. NMD's nameplates have been on the market for nearly 2 decades and have been highly evaluated by customers for their durability.

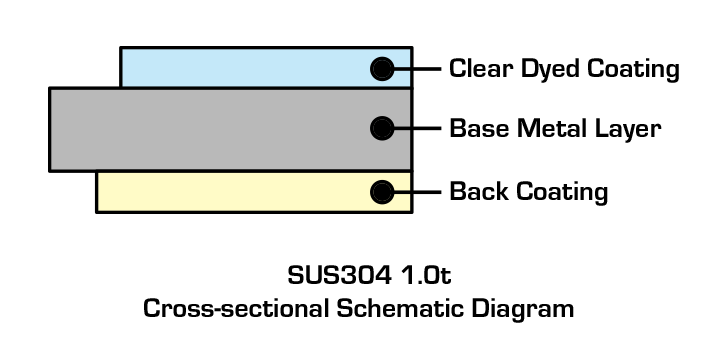

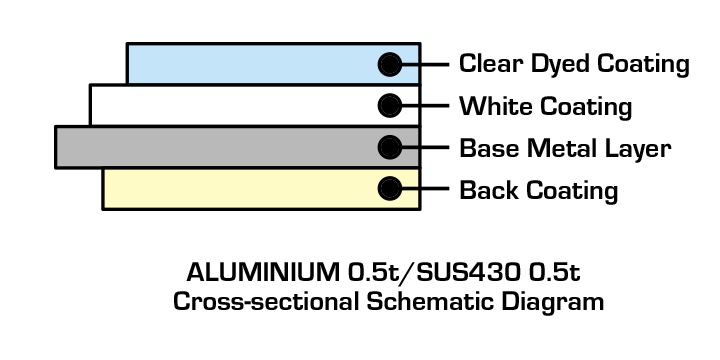

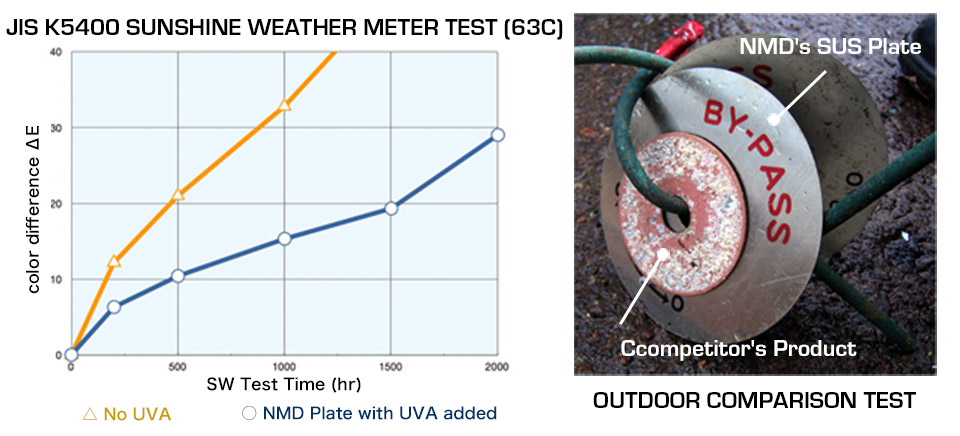

Our nameplates are manufactured by penetrating ink into the resin coated metal plate to express the design, and the metal surface is well protected. In addition, the resin (clear coating) layer contains anti-pollution agents and UVA to prevent fading. The back side is also coated with a clear coating to provide excellent corrosion resistance.

This high performance has been verified by JIS durability, weathering, and corrosion resistance tests and coastal exposure tests over a period of five years. It has also been confirmed by weathering and corrosion resistance evaluation test conducted by Otake Research Center of Chugoku Marine Paint Ltd.

A shipyard conducted a comparison test between our products and etched nameplate (made of BRASS). They hung our SUS nameplate and our competitor's etched nameplate at the quay for 6 months. There was no change on NMD's nameplate, our competitor products showed "white powdery substance and reddish surface" (see photo above right).

Excellent Visibility and Expressiveness

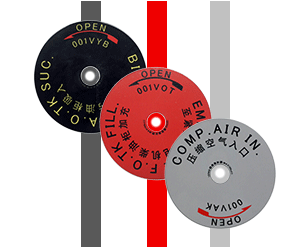

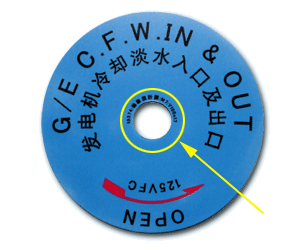

NMD's metal nameplates are digitally printed in color for high visibility and expressiveness. Since the price does not change depending on the number of characters or colors, you can color the nameplate for each category or add additional information to the nameplate itself. This makes the nameplate greatly recognizable and manageable.

Take More Advantage of NMD Technology

NMD's metal nameplates can be used anywhere onboard from exposed areas and engine rooms to passenger cabins, thanks to the versatility of sublimation thermal transfer technology.

Color-coordinate Valve Plate & Handle

By using the same or similar color for the valve handle and the nameplate, you can increase the visibility and make it easier to paint the valve handle. The handle painting can even be omitted.

Print Additional Info in the Hidden Area

Add ship number, specification sheet name etc. in the hidden area to facilitate inventory management. Print zone name or plate size to make installation work on site faster and more accurate.

For more information on reducing management costs, please visit the "Efficiency" page.

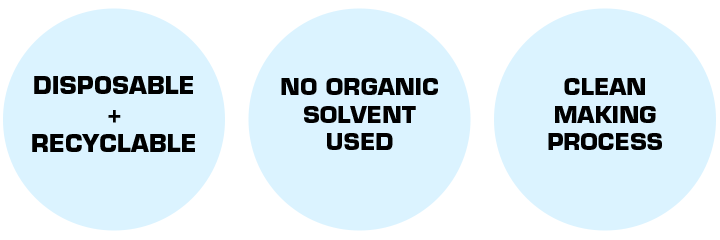

Eco-friendly, Naturally.

As the deterioration of the global environment is gradually becoming more serious, it is only natural that the manufacturing process and materials used in products must be environmentally compatible in order to fulfill corporate social responsibility.

The key technology of NMD's nameplate, sublimation thermal transfer, is a simple and clean production process. Not only no chemical treatment is required, but also the nameplate itself is environmentally friendly.

For example, metal nameplate products can be incinerated or recycled. After they are no longer needed, they can be handled as regular aluminum and stainless steel recycling products. In addition, the products do not contain any materials such as polyvinyl chloride that generate hazardous substances when burned, and no organic solvents are used in the manufacturing process.

When compared to products using the corrosion etching method, the difference is clear. The etching method usually requires not only enamel ink, but also organic solvents, photosensitive materials, ferric chloride, and lead-based chemical agents for sensitization, cleaning, and corrosion during the production process.

Conforms to the Latest JIS Standard

Nippon Maritime Display, as a leading company in the field of marine nameplates, has participated as a member of the committee of Japan Ship Technology Research Association (JSTRA) for JIS standardization for marine nameplates. This project came to fruition as a newly established JIS standard on March 31, 2008.

NMD's ship's nameplates conform to JIS F0104 (Japanese Industrial Standard: Ship's Nameplate Design Standard).